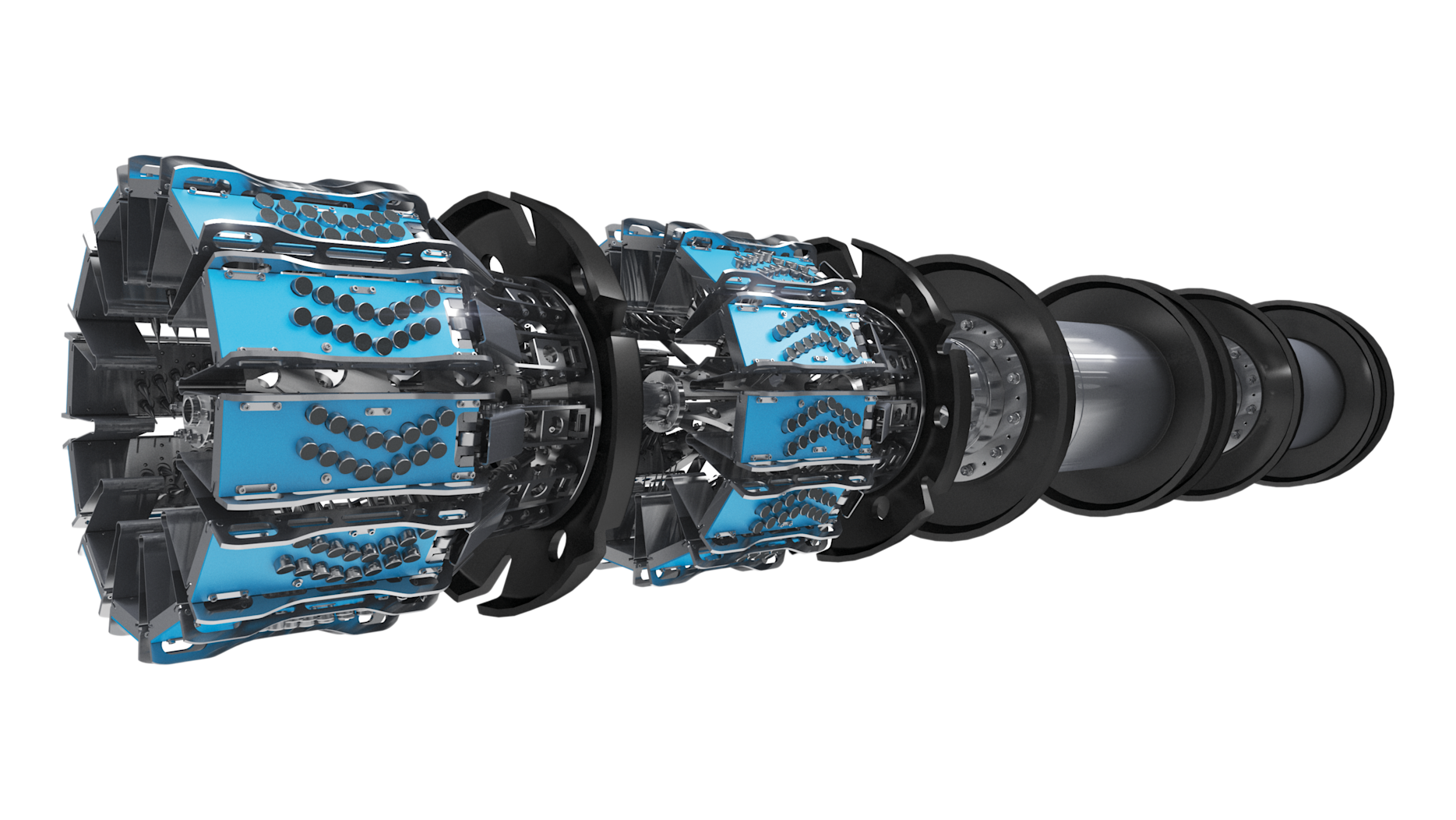

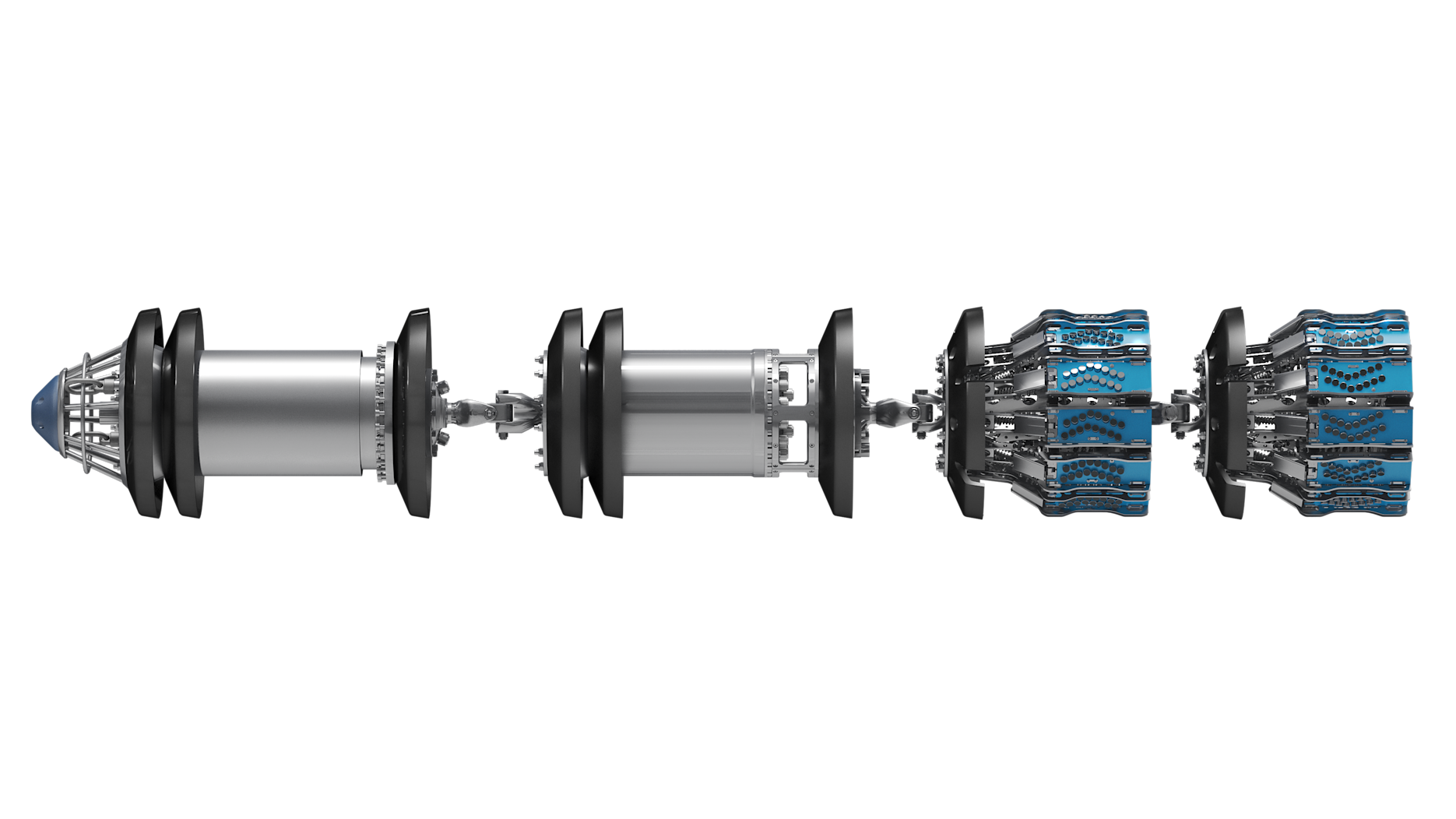

The EVO series ultrasonic inspection tools is NDT Global’s premiere solution for liquid pipelines.

These systems can be used to detect a range of defects along with their sizing, orientation, characterization, and predicted failure pressures. In the hands of our analysis team, this information is translated into a complete picture of the asset’s current health, along with the most accurate predictions about its future health based on existing operating conditions.

There are a number of operational advantages that come with our EVO series inspection tools. Chief among these advantages is the reduced/minimized risk to asset health and efficiency as the inspection occurs. Our EVO series was designed to quickly traverse the most challenging pipelines with minimal risk of failure, all while collecting the data that operators can confidently use to make the best decisions about their asset. This speed is complemented by its range of diameters, with tools ranging from 6” to 48”. Rounding out EVO’s operational efficiency is the number of technologies that can be deployed in a single inspection. Instead of having to run multiple inspections to collect data on individual feature types, EVO can collect all feature data – cracks, cracks in dents, dents and ovalities, metal loss, etc. – in a single run, reducing the time needed to perform these inspections, increasing pipeline efficiently.