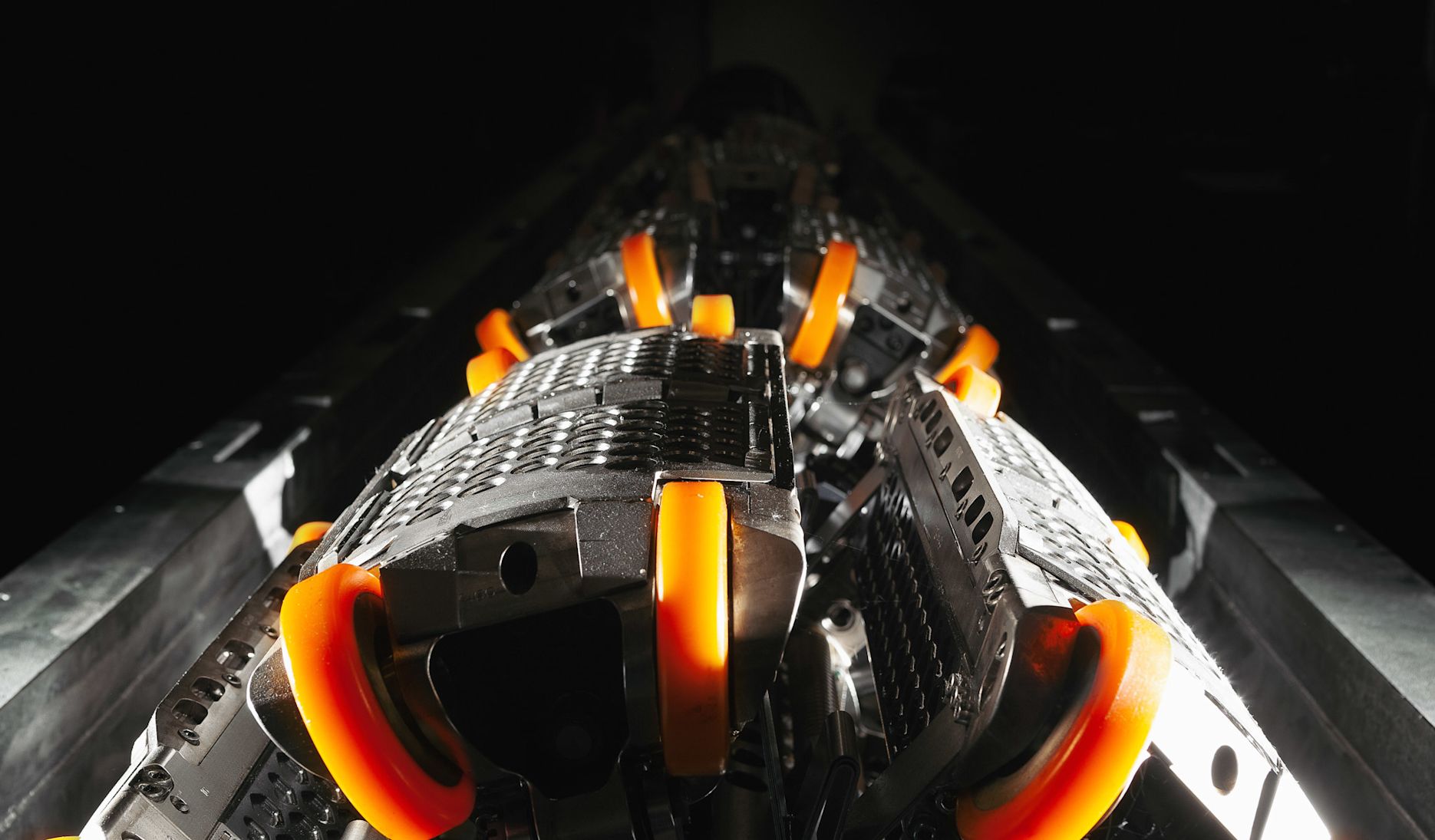

Having successfully been awarded the RFP, NDT Global began extensive technological research assessments of operational and other constraints which led to the development of an ultrasonic phased array inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… platform - PROTON™.

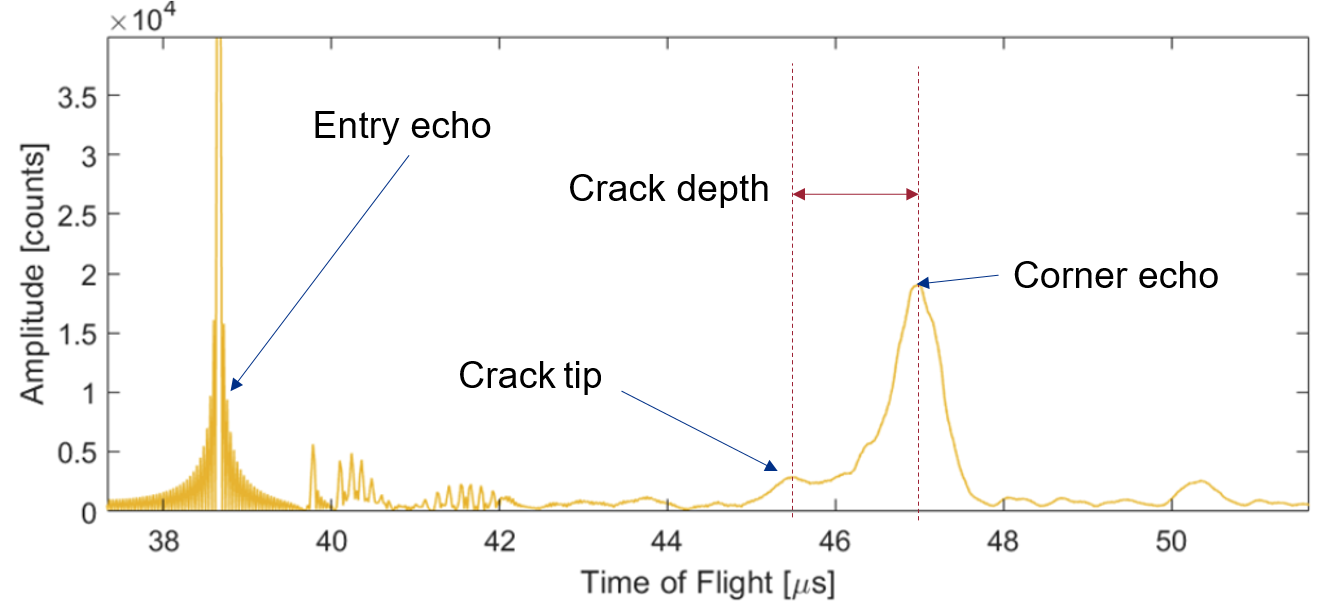

This technology provides crackA fracture or discontinuity in the wall of a pipeline, where the material is separated or broken, potentially compromising the integrity and safety of the pipel… and local wall thickness measurements in a single platform. Phased array technology can be configured via firmware for sample scenarios that include shear wave (crack) and/or compression (metal lossRefers to the reduction in material thickness or cross-sectional area of a pipe due to corrosion, erosion, or other forms of degradation. ) samples without mechanical modifications to the tool. Having the flexibility to configure our solution allows us to quickly optimize for the environmentSurroundings or conditions (physical, chemical, mechanical) in which a material exists. The environment plays a significant role in pipeline design, constructio… such as medium, velocity, weldLocalized coalescence of metals produced by heating the materials to the welding temperature, with or without the application of pressure, or by the application… type (DSAW, ERW, FW), and featureGeneral term for an anomaly detected during an assessment. Features can be anomalies, components, nearby metallic objects, welds, appurtenances, or some other i… type to obtain the best data possible for the individual application and increase operational efficiency.

The achieved performance enabled the operatorAn entity or organization responsible for the operation, management, and maintenance of a pipeline system. The operator is entrusted with ensuring the safe, rel… to move forward with a crackA fracture or discontinuity in the wall of a pipeline, where the material is separated or broken, potentially compromising the integrity and safety of the pipel… management program that successfully eliminates the need for hydrostatic testing on a challenging pipeline. PROTON has been accepted by the operator based on the performance against specifications. A robust qualificationThe process of validating, through tests and analysis, the performance specifications of an inline inspection (ILI) system. program, including a large set of pump test results, and a dig program with metallurgical validation allowed for acceptance with high confidence.