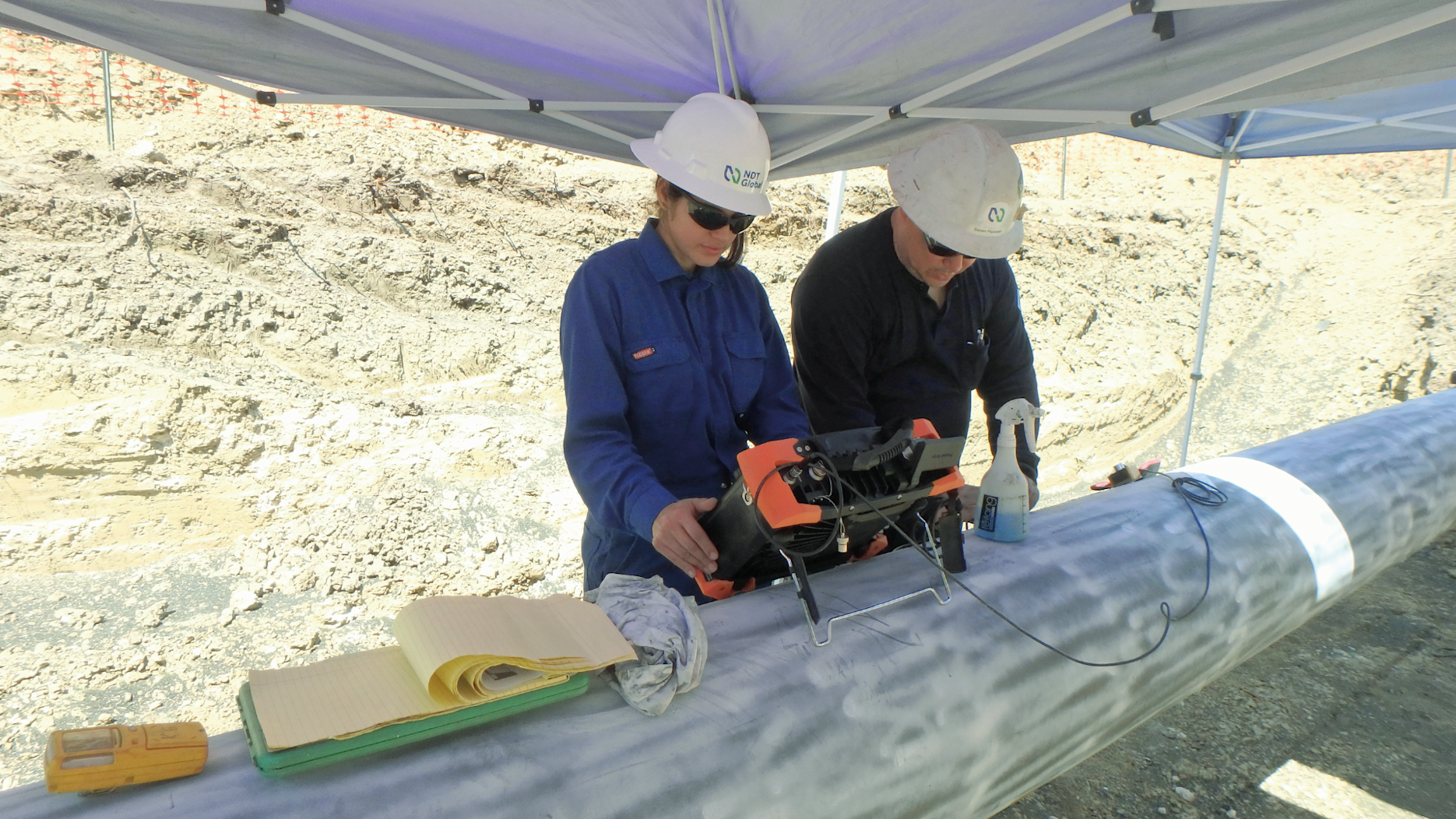

A North American pipeline operatorAn entity or organization responsible for the operation, management, and maintenance of a pipeline system. The operator is entrusted with ensuring the safe, rel… contracted

NDT Global to inspect an 18" Natural Gas Liquid

(NGLNGLs are hydrocarbons that are commonly found in association with natural gas deposits. They are composed of various hydrocarbon compounds, including ethane, pr…) pipeline for cracks, including hook cracks.

The pipeline transported blended NGL, which

made the inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… process complicated by the

nature of the medium.

Performing ultrasonic crackA fracture or discontinuity in the wall of a pipeline, where the material is separated or broken, potentially compromising the integrity and safety of the pipel… inspections in

a challenging medium such as blended NGL requires a thorough understanding of certain

parameters. One of the biggest challenges is determining the sound velocity in the medium

as changes in operational and environmental

conditions such as pressure and temperature can

affect ultrasoundRefers to sound waves with frequencies above the upper limit of human hearing, typically above 20,000 Hz. Ultrasound is used to determine wall thickness and to … propagation angles and lead to

measurement degradation.

Typically, when faced with a challenging medium,

the inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… tool is deployed in a batch of a

standard medium, such as diesel. However, in

this instance, the operatorAn entity or organization responsible for the operation, management, and maintenance of a pipeline system. The operator is entrusted with ensuring the safe, rel… sought a solution that

could be deployed directly in the NGLNGLs are hydrocarbons that are commonly found in association with natural gas deposits. They are composed of various hydrocarbon compounds, including ethane, pr… product.

Working closely with the pipeline operator, an

extensive testing and validation process was

initiated.