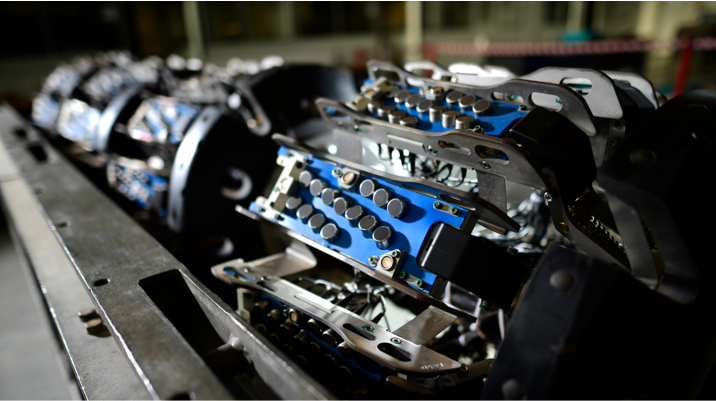

NDT Global has a history of innovation, adapting legacy technology and creating new technology to meet customer integrity management requirements.

Customers requested the ability to identify and size cracks outside of the scope of traditional inspection methodologies. Specifically, tilt and skew limitations made accurately sizing axial cracks in the pipe body and long seam difficult. Our solution was to develop Eclipse, which employs a pitch and catch sensor configuration. The result is the most advanced crack detection and sizing ILI technology to date.

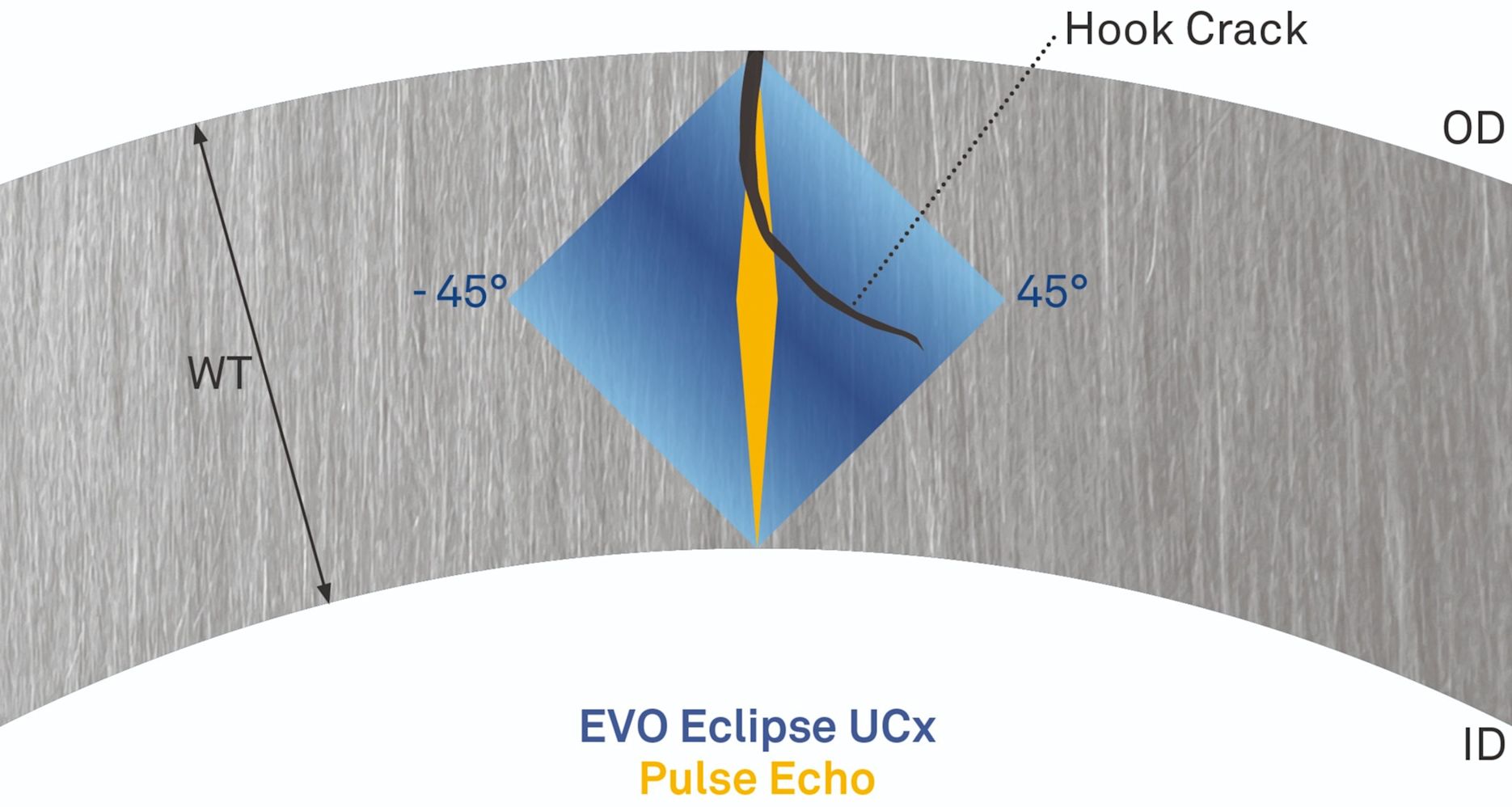

NDT Global’s latest crack detection technology provides high-resolution feature depth sizing enabled by an alternate configuration of transducers when compared to previous generations of the technology. Traditional crack sizing methods were limited by a 10-degree constraint from the angle of tilt. Pitch and catch technology expands the area of accurate observability beyond 10 degrees, allowing for the sizing of features with a tilt of up to 45 degrees. As a result, these complex features can be located and sized in the long seam or the pipe body i.e., hook cracks in the long seam.