A crude oil pipeline in Canada presented a particularly challenging scenario for NDT Global. Short, branched axial cracks located close to the girth welds had been observed. But these attributes created depth-sizing complexity for ultrasonic inline inspection tools. The assessment of such atypical flaws called for highly innovative techniques and an out-of-the-box approach. Against this background, experts from NDT Global worked closely with the customer to develop the best-fit solution. The goal was to gain greater insight into the nature of the cracks while overcoming the sizing limitations of conventional inspection technology. To this end, a series of analytical tests and experimental assessments were performed.

Case Study

Evaluation of Cracks in a Petroleum Pipeline

The Challenge

The Solution

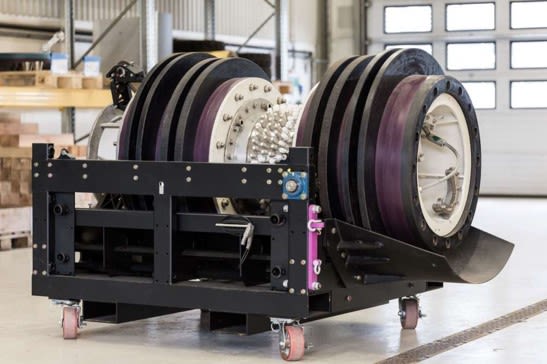

Engineers from NDT Global carried out extensive investigations to gain visibility into overall pipeline integrity. Their analysis included inline pull-testing conducted in a laboratory using cut-outs from the pipe, as well as non-destructive examinations in both real-world and laboratory settings. In addition, studies were undertaken to quantify the circumferential, radial and axial distributions of hoop residual stresses in the line and to simulate internal stress corrosion. The team deployed ultrasonic inspection tools equipped with sensor carriers and transducers to provide full circumferential coverage of the pipeline surface. A customized approach was needed as standard tools are not generally able to detect cracks of such a short length.

The Results

In-depth insight into crack complexities which were found to arise from the short crack lengths and close proximity to girth welds

Full-scale pull-testing program to establish the inspection tool’s sizing and detection capabilities

Laboratory non-destructive experiments to better understand the impact of crack orientation on sizing

Discover the Power of Clarity.

Whether you’re ready to schedule an inspection or have questions about our process, our team can help get you started.

Contact Us© Copyright 2026. NDT Global. All Rights Reserved.