The ultimate measures of an inline inspection report’s value are its usability, its accuracy, and its insightfulness.

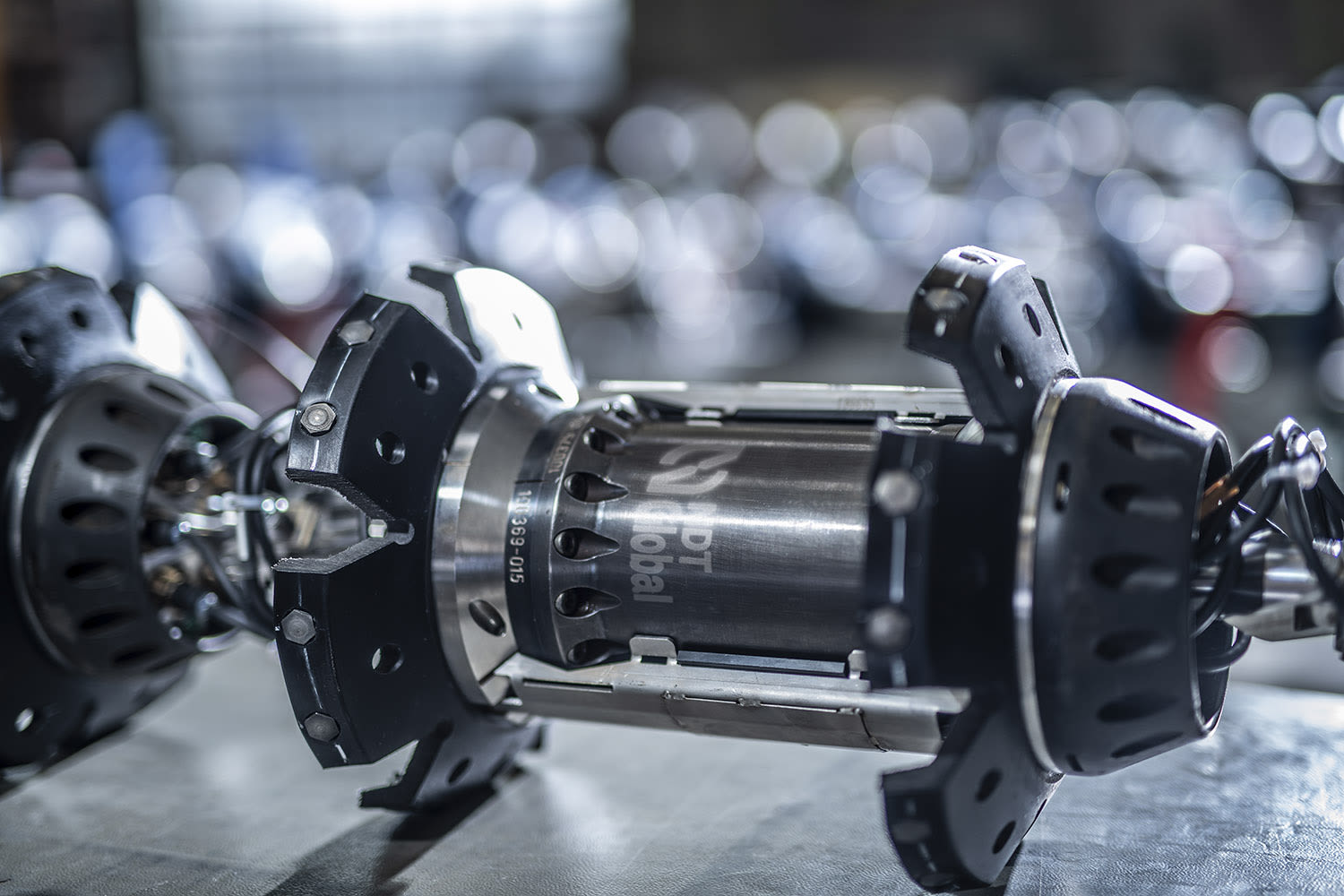

NDT Global has been honing the value of our Inline Inspection Report by focusing on these three measures for more than two decades. Our commitment to the excellence and usefulness of this report is ongoing, meaning that every customer gets a best-in-class report when they partner with NDT Global.

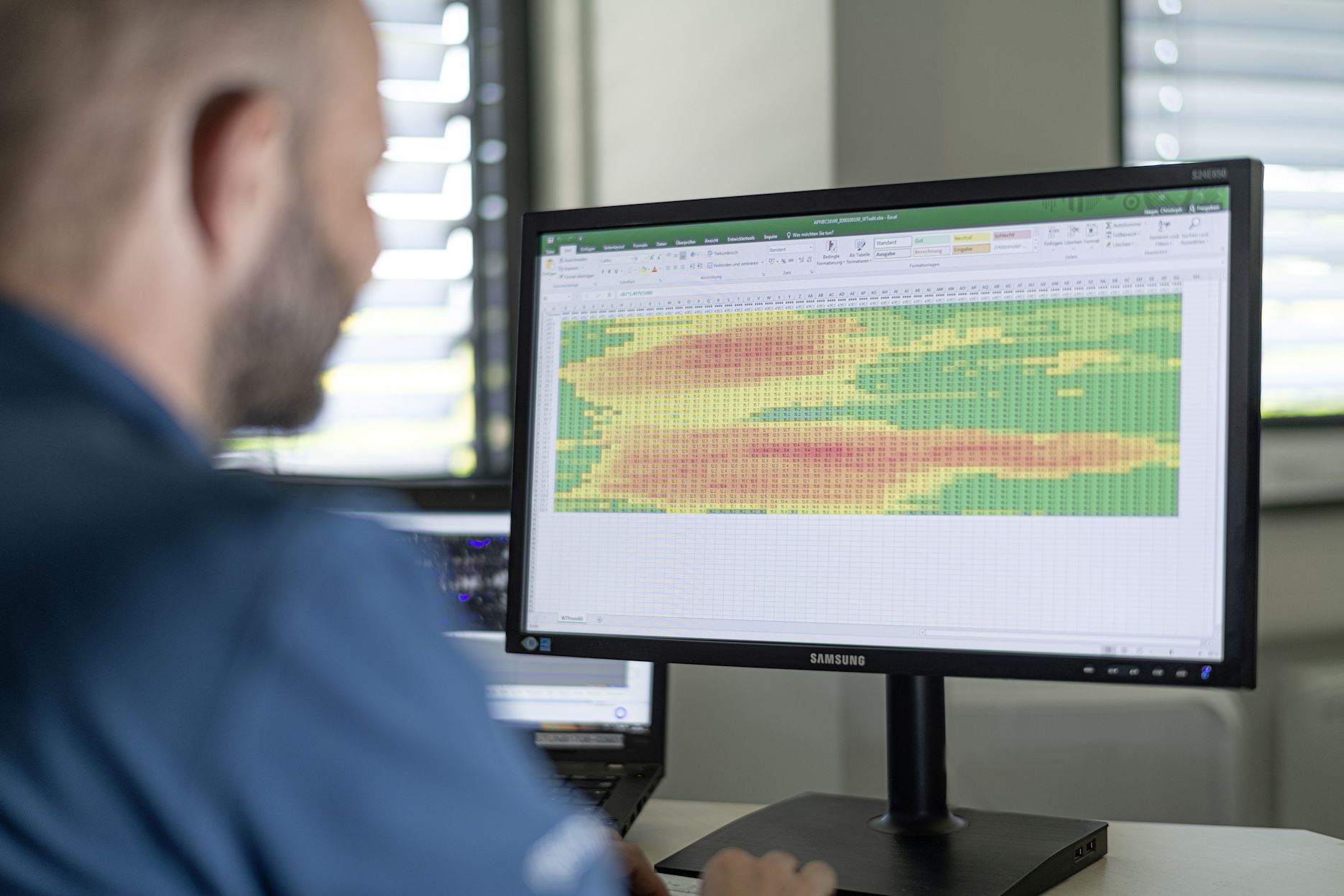

During the course of an inspection, NDT Global gathers gigabytes-worth of data. The sheer volume of this data can make using it a daunting challenge. As a result, we’ve focused as much energy on making this information useful as we do on developing the hardware and software to collect it. Our team of experienced analysts developed our Inline Inspection Report with the goal of making it immediately actionable. This focus is expressed in the report by sorting through millions of data points about features and determining the ones that have the potential to be most injurious. These features are highlighted with annotated screenshots and charts that let customers know where these features are located, their sizing and orientation, and their potential for injuriousness. This straightforward report formatting was developed to deliver the clarity for which NDT Global has come to be known.