Learn about Aly Marson, our newest Commercial Account Executive for the US region, through an exclusive interview. Discover her background, insights, and plans to educate companies about the benefits of ultrasonic technologies.

What is your background and experience in the inline inspection and pipeline integrity industry, particularly within the US region?

With an engineering background, I launched my career at an international oil company in Houston, Texas. Since joining NDT Global as a Project Manager in 2017, I have gained extensive experience managing inline inspection projects within our operation team in Houston, overseeing technology development in Stutensee, Germany as part of our Research and Development team, and contributing to strategic projects in our Commercial sales team. All these efforts revolve around inline inspection with a significant emphasis on international customer collaboration.

What drew you to this industry, and what excites you the most about working in this sector?

I was drawn to the ILI industry for its technology and its applications, especially within preventive diagnostics. The concept of inline inspection aligns with my affinity towards proactively addressing potential issues rather than reacting to them. Working in this sector allows me to collaborate closely with clients, supporting them in mitigating threats and actively contributing to the development of new technologies.

In your opinion, what are the key challenges and opportunities within the pipeline industry today, and how do you envision addressing them in your role?

Gas pipelines are the next big step for NDT Global, our technology stream is evaluating and developing different applications to address some of the most challenging threats, like crack inspection in gas pipelines or threats from geohazards. I look forward to engaging with existing and new partners to further enhance those developments, and to be able to deliver novel solutions to provide safer pipeline operations.

Ultrasonic technology is gaining traction in various industries. How would you explain its significance and potential benefits to companies that may not be familiar with it, especially in the context of pipeline integrity?

Ultrasonic technology has emerged as a valuable asset in various industries, including its application in ensuring pipeline integrity. The high precision and direct measurement nature of ultrasonic measurements allows for accurate detection of defects, corrosion, and wall thickness variations, enabling proactive maintenance and preventing potential issues that could compromise pipeline integrity.

From your perspective, what are some key challenges companies face when it comes to pipeline integrity, and how do you believe our innovative technologies can address these challenges?

In the pipeline integrity sector, companies often face challenges such as aging infrastructure, the need for timely inspections, and potential environmental and external threats. Our advanced technologies, including innovative UT tools, offer a comprehensive solution by providing accurate pipeline condition data. This proactive approach enables companies to detect and address potential issues before escalation, minimizing downtime and preventing costly repairs.

What common misconceptions or hesitations might companies have about adopting ultrasonic technology for their pipeline inspection, and how do you plan to address these concerns?

Common concerns include implementation costs, perceived complexity, and uncertainties about the technology's reliability. In response, we emphasize transparent communication and education, showcasing the long-term benefits, such as cost reduction, minimized downtime, and improved safety. By focusing on clear communication, education, and providing tangible evidence of the technology's effectiveness, we aim to build confidence among companies considering the adoption of ultrasonic technology for pipeline inspection. Additionally, NDT Global offers a range of technology offerings and integrity solutions to assist operators with not only building an ILI management framework but also developing a proactive and sustainable program based on the latest industry research and assessment methods.

What differentiates NDT Global from other ILI companies?

Our commitment to customer service and cutting-edge technology distinguishes us from other inline inspection companies. We prioritize customer satisfaction by providing personalized and responsive support throughout every stage of our engagement. Our dedicated team is always ready to address client needs, ensuring a seamless and positive experience.

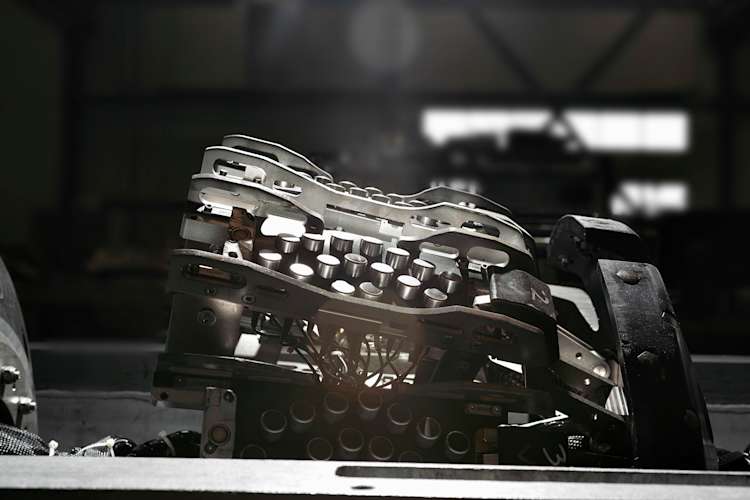

In terms of technology, we pride ourselves on staying at the forefront of innovation. Our ILI services leverage innovative technologies, such as advanced ultrasonic and data analytics tools, enabling us to deliver precise and comprehensive insights into pipeline integrity.

Looking ahead, what excites you the most about the future in the industry, and how do you plan to leverage these advancements in your role?

I am excited about the continuous evolution of ultrasonic technology in the industry, anticipating enhanced data resolution and accuracy with improved sensor technologies. The prospect of integrating artificial intelligence and machine learning into ultrasonic data analysis is particularly promising, revolutionizing our ability to predict and prevent issues. These advancements align with my commitment to staying at the forefront of innovation. Additionally, I look forward to future technological developments, which will not only expand our portfolio but also open doors to new markets and opportunities to connect with new people.