BP Angola needed a highly accurate baseline inline inspection (ILI) of its 36 km (22 mile) Plutao offshore deepwater (up to 2,000 m/6,500 ft) flowline and riser systems. The baseline inspection is part of BP standard practice and provides a true blueprint of the pipeline, giving exact internal inspected status following commissioning.

When the BP Subsea Projects Team began the ILI campaign, its first challenge was to thoroughly prepare for every eventuality. Unexpectedly the Plutao operation experienced an unplanned shutdown; giving the team a new window of opportunity to start the project ahead of the initial schedule, with the condition that mobilization had to start within 24 hours to coincide with this unforeseen shutdown.

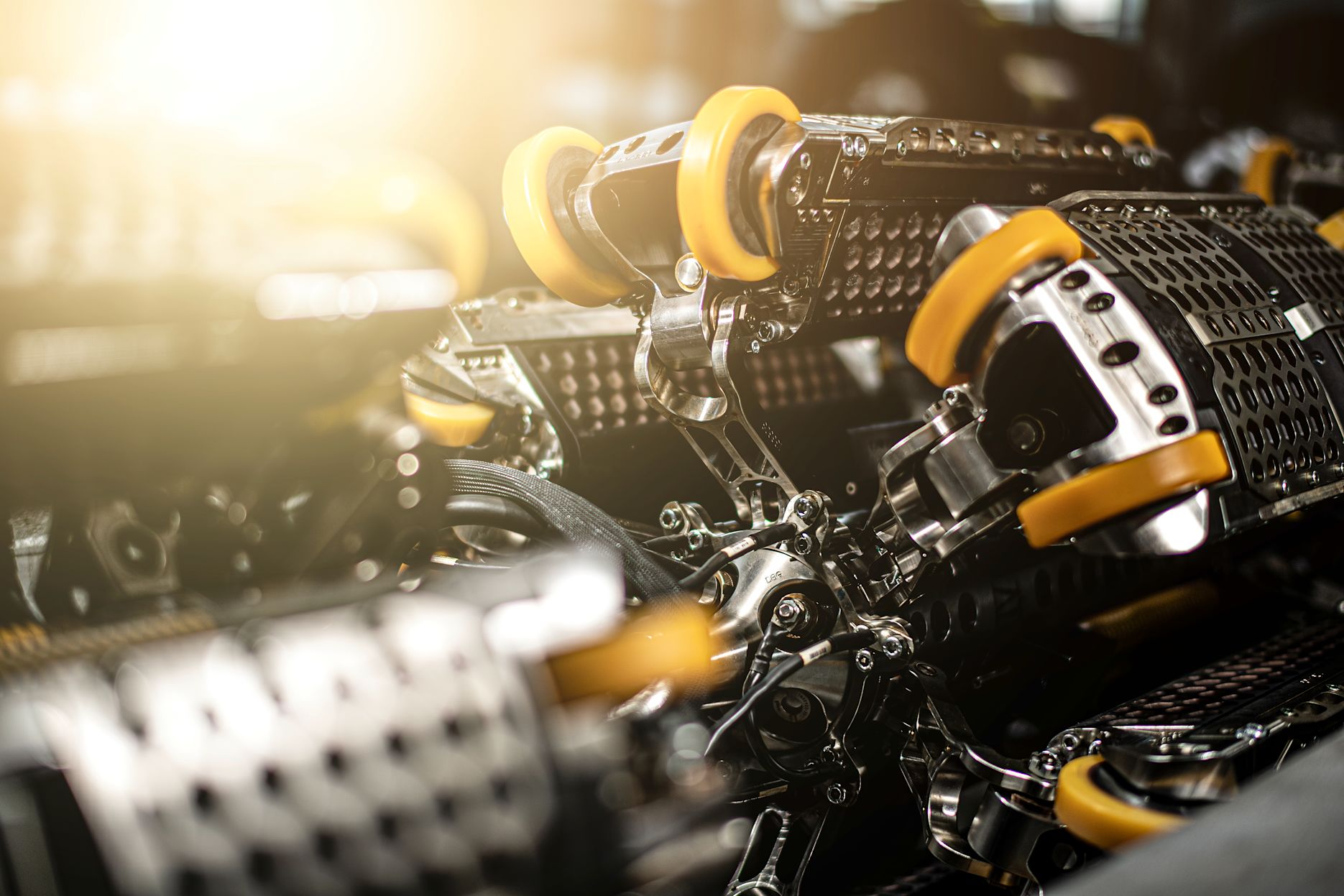

To run the ILI equipment first requires cleaning the line with a series of pigs, each designed for a specific task. The first is a foam pig to ensure all valves are fully open. Then, a de-sanding pig was used to dislodge accumulated sand and wax. This was also used to sweep away any debris. Finally, a gauge plate pig with a special disc matching the diameter of the pipeline is run to verify the pipeline has the required bore for the inspection tool.

Once the team was mobilized, initial cleaning pigs in the line went as planned. The debris returned was minimal, indicating the line was cleaner than expected. A decision was then taken to run the gauge pig ahead of schedule.

When it returned to the surface after its subsea odyssey, the gauge disk resembled a bowl rather than the flat plate that had set out on the journey. This identified a problem. The challenge now was to engineer a solution in record time to safely run the ILI tool below its current design limit, keeping risks within acceptable levels.