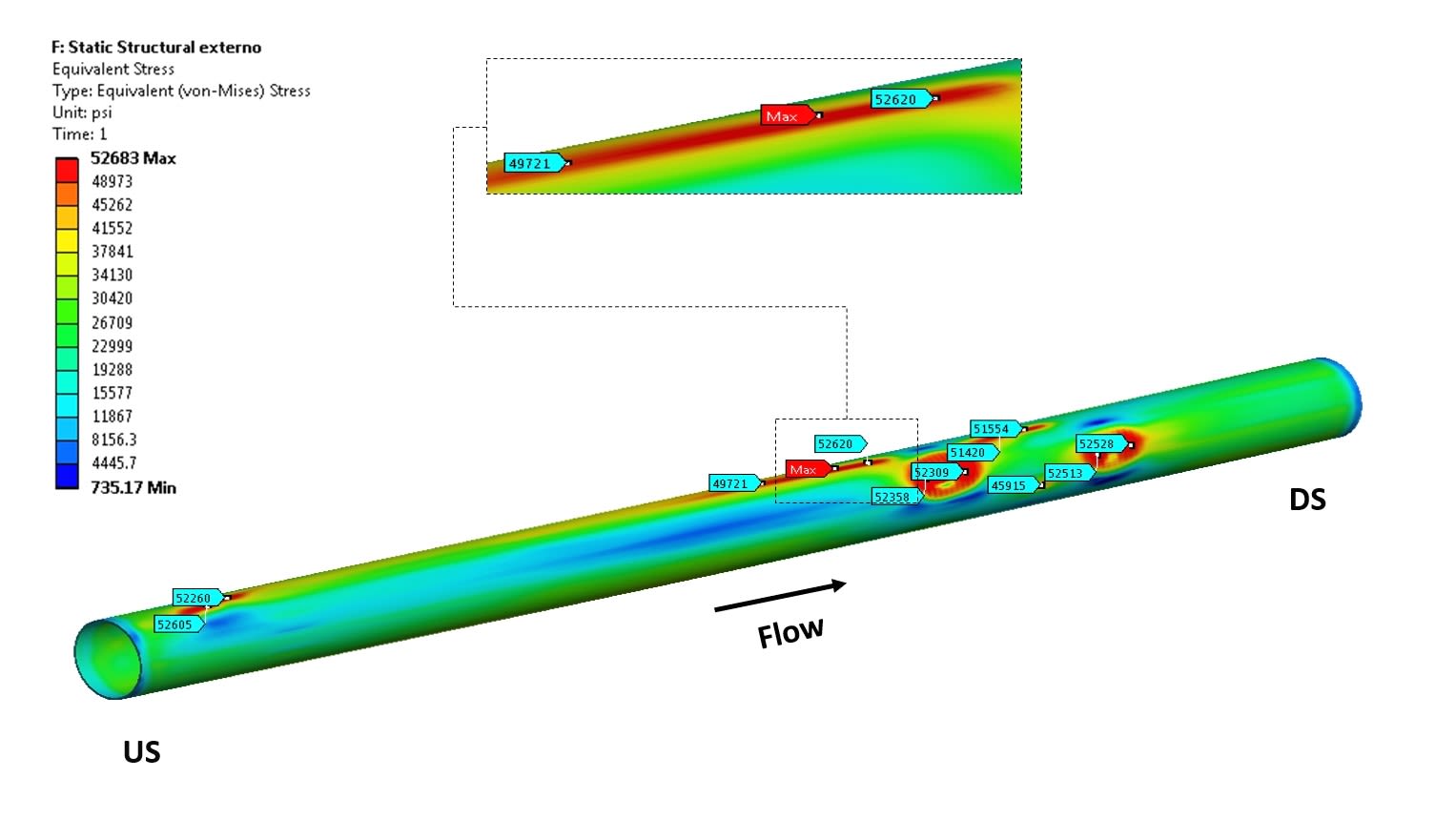

NDT Global’s finite element analysis (FEA) was developed in response to traditional assessment methods that yielded results that were too conservative.

This conservatism can cause operators to perform unnecessary remediations and overspend on mitigation efforts that were not required. Depending on the nature of the threat, operators can save both time and money with NDT Global’s FEA.

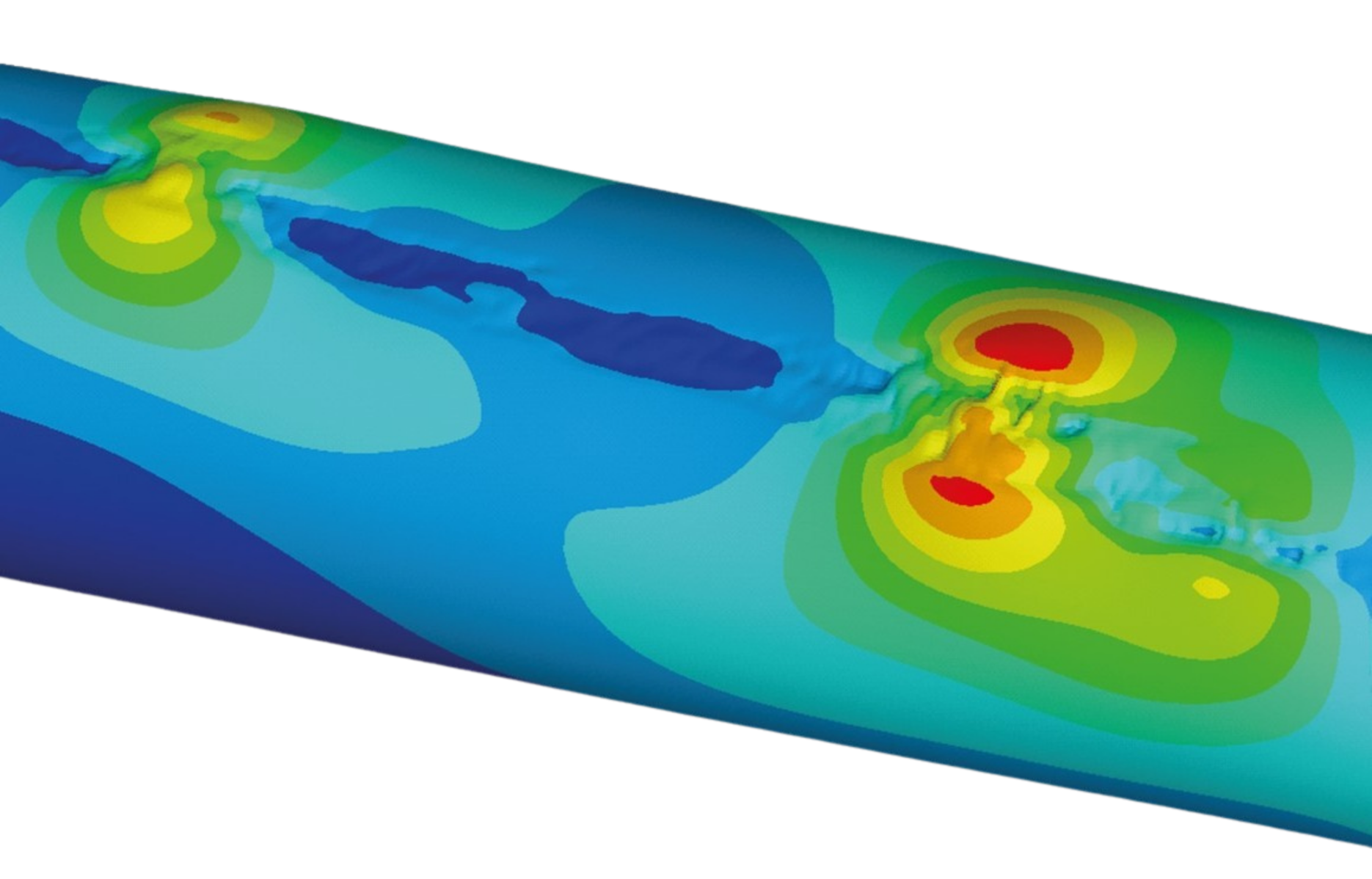

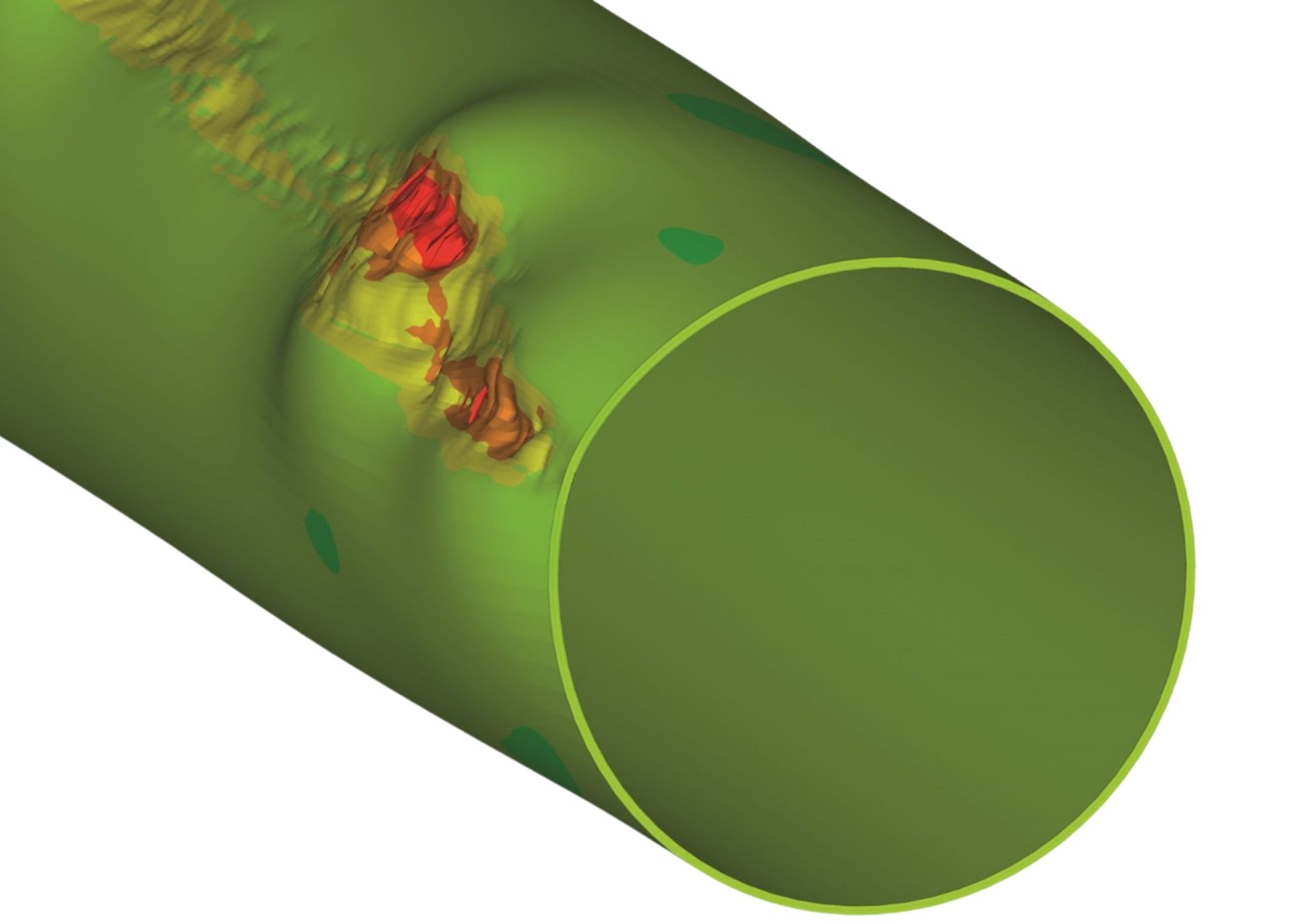

Unlike conventional methods, NDT Global’s FEA uses best-in-class 3D geometry mapping to not only identify anomalies in the pipeline, but to also account for the specific variables associated with them. Our FEA can also provide an assessment of combined anomalies (i.e., dents, cracks in dent, metal loss, etc.), a feature not found in traditional finite element methods.