Interested in learning more about how NDT Global’s ultrasonic inline inspectionA method used to assess the the integrity and condition of pipelines. It involves the use of specialized tools that are inserted into the pipeline and propelled… technology can minimize threats to your liquid pipeline and maximize peace of mind? Contact us to learn how we can help.

NDT Global’s Acoustic Resonance Technology (ART) platform provides the leading gas pipeline operators with the insights they need to maximize the value of their assets and minimize environmental impact.

For operations with cracks that are particularly difficult to identify and size, our Pitch and Catch technology could be the key to smooth and profitable operations.

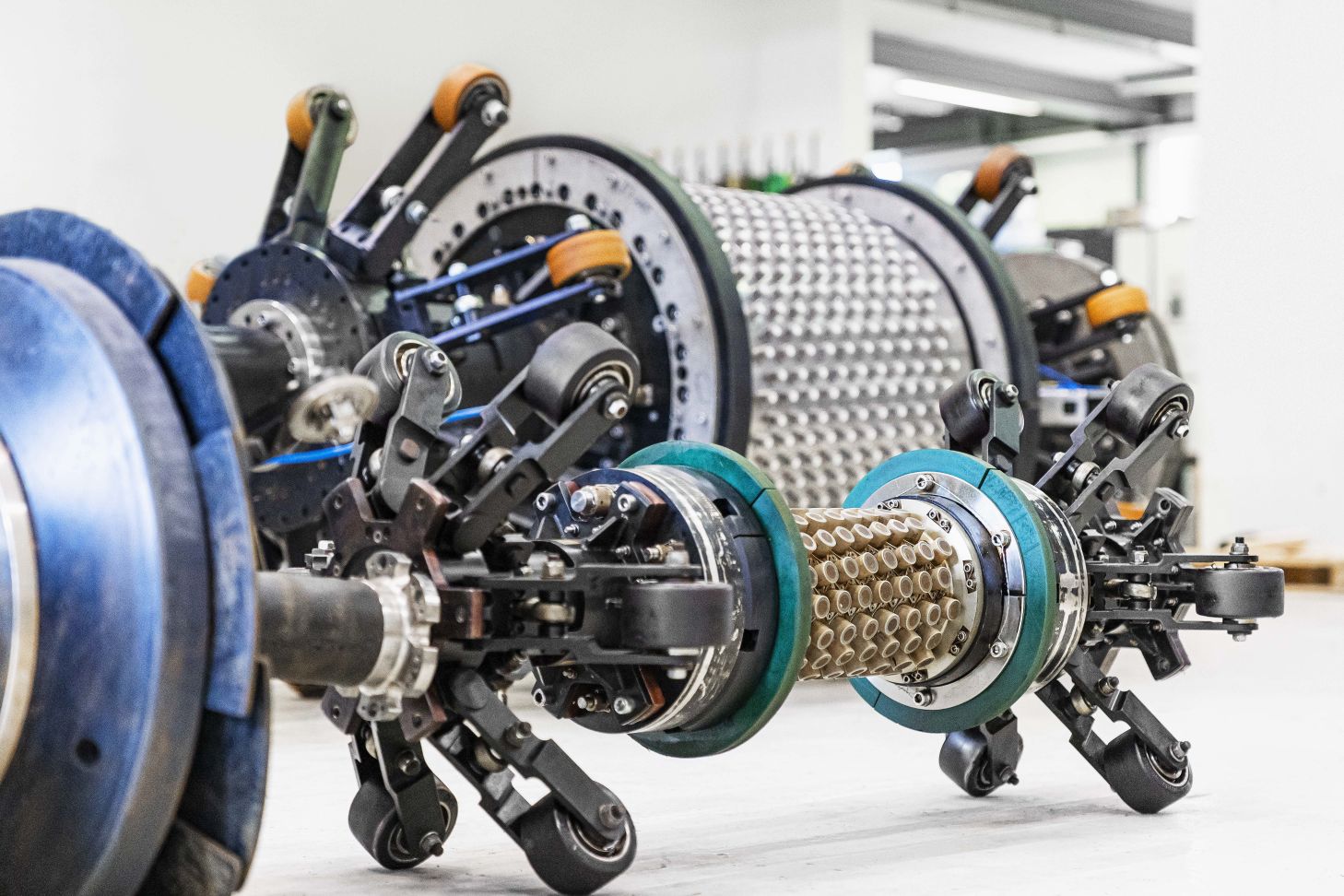

For metal loss, dents and ovalities, and crack detection in the most challenging pipe wall locations, NDT Global innovated Pulse EchoA common ultrasonic testing technique used in non-destructive testing (NDT) to detect and evaluate defects or anomalies such as corrosion, cracks, or metal loss… technology to give operators the precise information they need to identify, size, and remediate them. Learn how we can be your go-to partner for the most in-depth insights into your most challenging features.