When it comes to pipeline integrity, selecting the right inspection vendor is critical not only to safeguard assets but to meet regulatory requirements and prevent costly failures. Yet with numerous vendors in the market, how can operators confidently identify a reliable, proven partner?

At NDT Global, our approach is shaped by decades of hands-on experience and deep industry knowledge from leaders who understand the high stakes of pipeline inspection. Three of our commercial sales team share their insights into vendor selection.

Jim Costain, Director of Commercial Sales, has supported operators worldwide in developing integrity programs built on high-resolution data and trusted analysis.

Ron James, Director of Commercial Sales - MEAA, brings regional expertise and insight into navigating inspection challenges in diverse operating environments.

Craig Hall, Commercial Account Executive, partners closely with operators to ensure inspection solutions are aligned with real operational needs and regulatory demands.

Their collective experience highlights the importance of selecting a vendor that delivers more than just a tool, it’s about insight, reliability, and long-term integrity success.

Tool Capabilities and Resolution

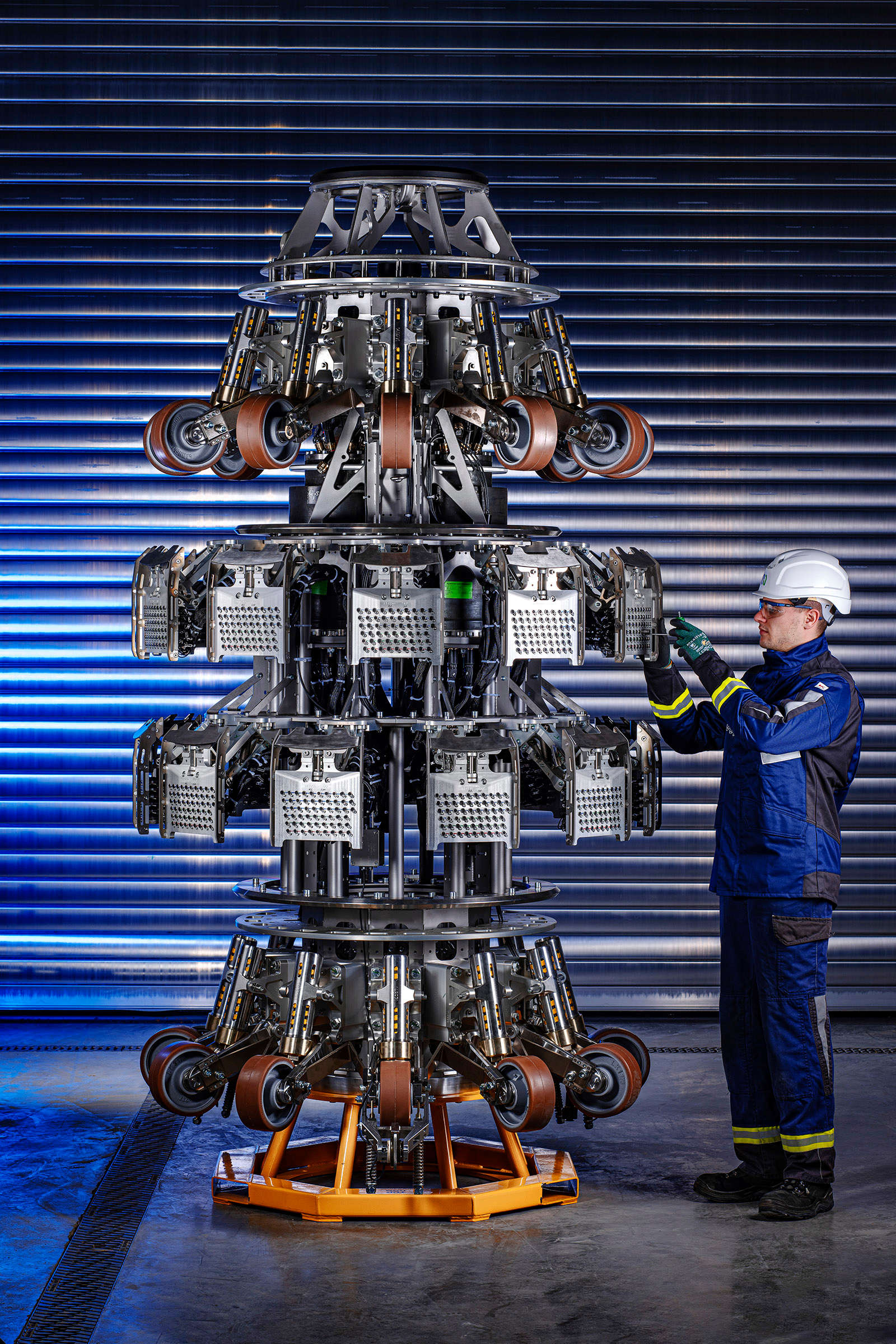

Accurate pipeline inspection hinges on high-resolution tools capable of detecting subtle and early-stage anomalies. Without precise data, defects can go undetected or misclassified, giving operators a false sense of security. This can delay preventive action and increase the likelihood of failure.

"Over a three-year period, one operator's inspection program using NDT Global’s Ultrasonic Inline Inspection Technology identified more than 800,000 features, including over 40,000 laminations and nearly 1,000 crack-like anomalies. These insights enabled targeted repairs and proactive integrity planning that wouldn’t have been possible with lower-resolution tools." Jim Costain, Director of Commercial Sales

A low-resolution inspection approach may not detect corrosion types such as channeling, wall loss under deposits, or crack-like features, issues that can escalate if not properly identified and addressed. Using the wrong technology for a given pipeline condition has led to catastrophic outcomes.

Experience and Track Record

Experience matters in pipeline inspection. Inspection vendors with extensive field experience bring valuable insights into pipeline behavior across diverse conditions. Without this knowledge, vendors may deploy inappropriate tools or misinterpret data, resulting in poor decision-making.

For example, in one case, a pipeline failure occurred after years of using the same inspection approach that failed to identify channeling corrosion. The inspection provider persisted with MFL-A despite indications that an alternative technology was better suited. When the pipeline eventually failed, the previously reported features were found to be through-wall defects.

In another case, an operator awarded an inspection contract to a significantly lower-cost provider claiming to meet a stringent specification. When the pipeline later failed, it became evident that critical features had been missed entirely. A subsequent reinspection by NDT Global identified extensive through-wall corrosion that had not been reported.

“Selecting a vendor solely on price can lead to missed threats and pipeline failures. A quality-first approach not only protects assets but saves costs long-term by reducing rework, downtime, and emergency interventions.” Ron James, Director of Commercial Sales – MEAA

These real-world consequences highlight the risk of relying solely on cost when selecting an ILI vendor.

Compliance with Industry Standards

Inspection vendors must adhere to recognized industry standards such as API, ASME, and ISO. Non-compliance can result in unreliable inspection results, regulatory penalties, or even forced shutdowns.

NDT Global aligns its processes with global best practices, ensuring all inspections meet or exceed the expectations of industry regulators. This commitment not only enhances data integrity but protects operators from legal, safety, and operational risks.

Credibility and Reliability

Trust in your inspection vendor goes beyond a single run—it’s about consistent delivery of high-quality data and actionable insights. A credible vendor ensures that tool performance, data analysis, and reporting standards are upheld at every step.

Too often, we’ve seen cases where vendors underdeliver, promising high-spec performance at a low price point—only to miss critical threats. In markets where cost becomes the deciding factor, operators may unintentionally invite higher long-term risk and cost.

“The cost of a single unplanned repair often exceeds the investment in high-resolution inspection. Choosing the right tool and vendor from the beginning is not just a technical decision—it’s a financial one.” Craig Hall, Commercial Account Executive

Avoiding the Risks of a Poor Vendor Choice

When selecting an ILI partner, consider these key risks of working with an unproven or ill-equipped provider:

Missed or misclassified defects – risking undetected through-wall corrosion, cracks, or complex threats.

Regulatory non-compliance – exposing operators to fines or operational shutdowns.

Higher total cost of ownership – from emergency repairs, re-inspections, and loss of product.

Choosing a trusted partner with a strong technical foundation, proven performance, and a commitment to safety reduces these risks significantly. With 25 years of experience and a track record of accurate, reliable inspections, NDT Global continues to support operators in making informed, data-driven integrity decisions.