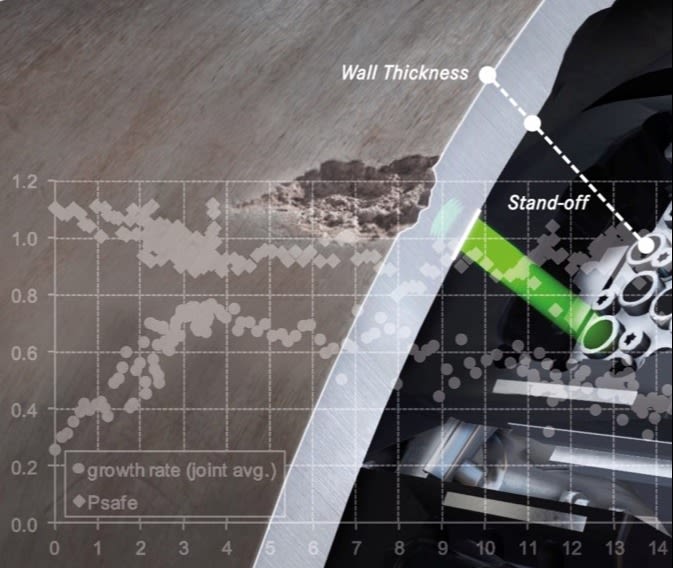

Feature Growth Assessment: Predicting featureGeneral term for an anomaly detected during an assessment. Features can be anomalies, components, nearby metallic objects, welds, appurtenances, or some other i… growth is among the most critical insights required to ensure the safe and profitable operation of a pipeline. NDT Global capitalizes on the high accuracy of our data to achieve the most realistic feature growth predictions. Over time, these signal-on-signal analyses provide the insights needed to maximize asset lifecycle, safety, and profitability.

Pipeline Movement Assessment: Pipelines are designed, to within millimeter levels of accuracy, to make sure they operate efficiently, safely, and profitably. Landslide, earthquakes, and erosions put all of those goals in jeopardy. In a single inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re…, our ultrasonic toolGeneric term signifying any type of instrumented tool or pig., coupled with an INS module, delivers the information needed to identify where movement is happening and what incremental strainRefers to the stress and deformation that a pipeline experiences due to external forces, such as ground movement, soil settlement, or external loading.

When … and riskA measure of loss in terms of both the incident likelihood of occurrence and the magnitude of the consequences. it’s introducing. Our run-on-run Pipeline Movement Assessments provide ongoing insights about how that movement is correlated to bending strainDeformation that occurs when a pipeline is subjected to bending or curvature. It is caused by external loads or forces that create a bending moment on the pipel…, circumferentialAn event that occurs or is measured along the circumference of a pipeline. It implies the direction or orientation that is perpendicular to the longitudinal axi… cracks, and other asset threats.

Dent Strain Assessment: In and of themselves deformations can cause throughput challenges. Left unattended, they can lead to cracks and other threats in your pipeline, disrupting service, affecting the environmentSurroundings or conditions (physical, chemical, mechanical) in which a material exists. The environment plays a significant role in pipeline design, constructio…, and reducing asset profitability. Our dentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal. strainRefers to the stress and deformation that a pipeline experiences due to external forces, such as ground movement, soil settlement, or external loading.

When … assessment was designed to identify these threats and then – through the analyses by our team of experts – give you the information you need to address the most critical risks and defer remediationThe appropriate actions taken to address or rectify issues, deficiencies, or anomalies identified in a pipeline system. It involves implementing corrective acti… for those that are nowhere near criticality.

Dent Profile Characterization: Of all the threats facing a pipeline’s operation, dents have the potential to be the most injurious. They can be harmful on their own but can be even more injurious if they are adjacent to other features like metal lossRefers to the reduction in material thickness or cross-sectional area of a pipe due to corrosion, erosion, or other forms of degradation. , cracks, or other defects. DentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal. Profile Characterization plays an important role in these dent observation measures because the potential threats that dents present are based on a wide array of factors.