NDT Global’s Diagnostic Insights are at the heart of the value that we offer customers. Our inspection tools collect the best data and our analysts provide the most concise insights that allow operators to make the best integrity management decisions for their business.

Diagnostic Insights

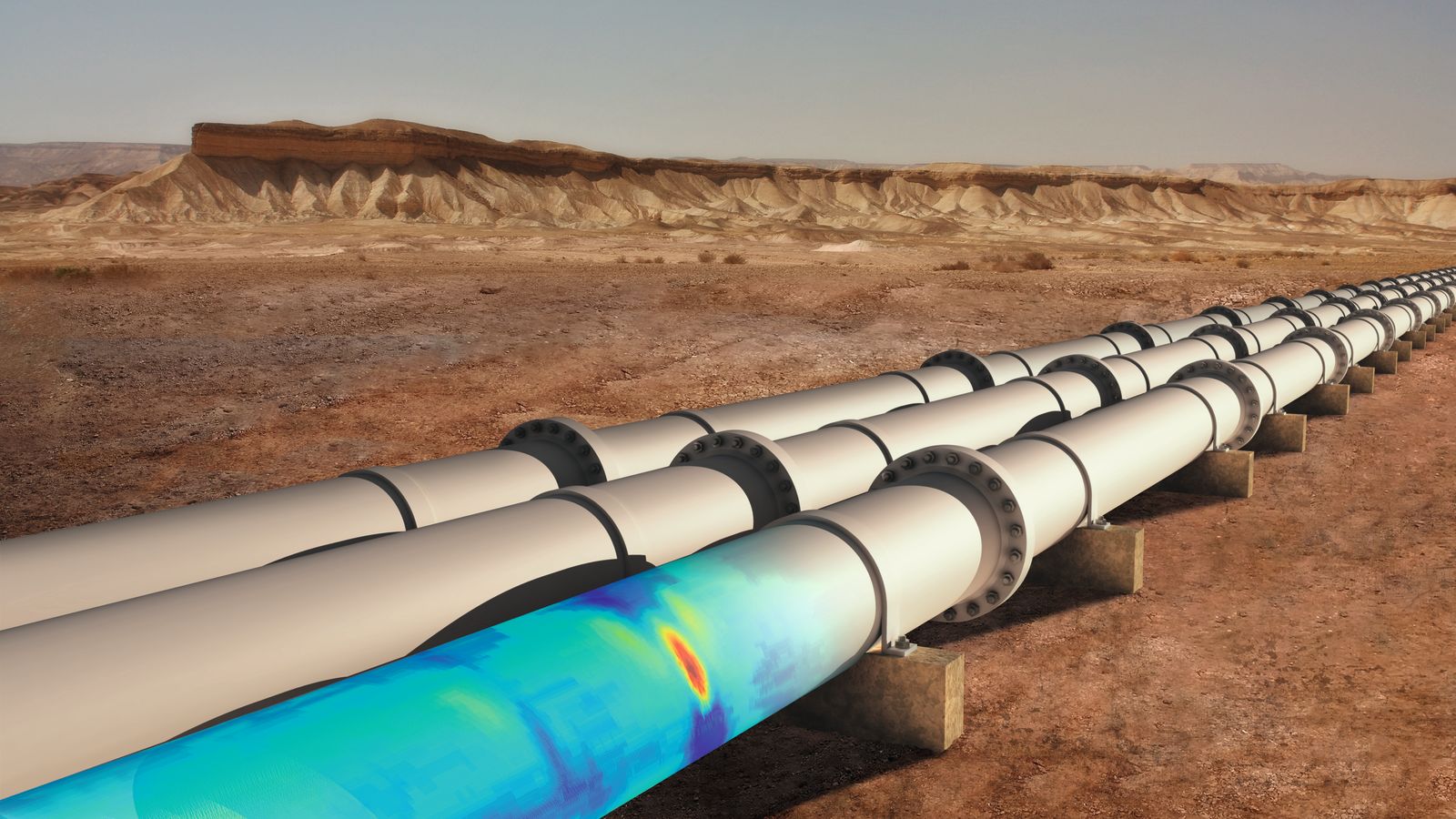

Our signature product is the Inline Inspection Report. Using the data gathered during an ultrasonic or acoustic resonance technology inspection (ART), this report takes millions of data points and transforms them into immediately actionable insights. This data is among the most critical in making informed pipeline management decisions.

The volume of data collected in a pipeline inspection can present a usability challenge. Without the right visualization tools, it can be difficult to look at data from different perspectives. Our OPTIX™ Data Visualization and Insights Platform was designed to meet this challenge. It’s a cloud-based business intelligence tool that allows customers to view NDT Global reports from virtually any device. It also allows for dynamic visualizations on a number of potential pivots, making OPTIX the best tool to extract the maximum value from an inspection.

NDT Global’s Integrity Assessments were designed to assess the risks to pipeline integrity. Our team of experts review the inspection data to provide operators with the most accurate integrity recommendations. The most comprehensive of these assessments is our fitness for purpose (FFP), which offers a customized view of each customer’s asset along with insights about to how to extend its usable lifetime.

Finally, our Integrity Consulting Services department offers fully customized analyses that dig deep into inspection data provided by us and/or third parties. Customers with specific needs that fall outside of the thresholds of our standard reports engage our Integrity Consulting Services team on a regular basis to provide them with the peace of mind and risk mitigation insights they need.

Discover the Power of Clarity.

Whether you’re ready to schedule an inspection or have questions about our process, our team can help get you started.

Contact Us© Copyright 2024. NDT Global. All Rights Reserved. - NDT Global is a Previan Business Unit