A dentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal. can be in combination with a stressThe internal forces and pressures experienced by a pipeline as a result of various factors, including internal and external loads, operating conditions, and env… concentrator in your pipeline.

In particular, unrestrained dents exposed to pressure cycles form a major threat since they often lead to fatigueThe process where cracks develop and propagate in a material under cyclic loading or repeated stress over time. It is a type of fatigue failure that occurs when… cracks. Whatever caused the dentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal. is most likely the cause of any coatingLiquid, liquefiable, or mastic composition that, after application to a surface, is converted into a protective adherent film. The coating serves as a barrier b… removal experienced, so corrosionThe deterioration or degradation of a pipeline caused by chemical or electrochemical reactions with its environment. Corrosion is a significant concern as it ca… could be an issue as well.

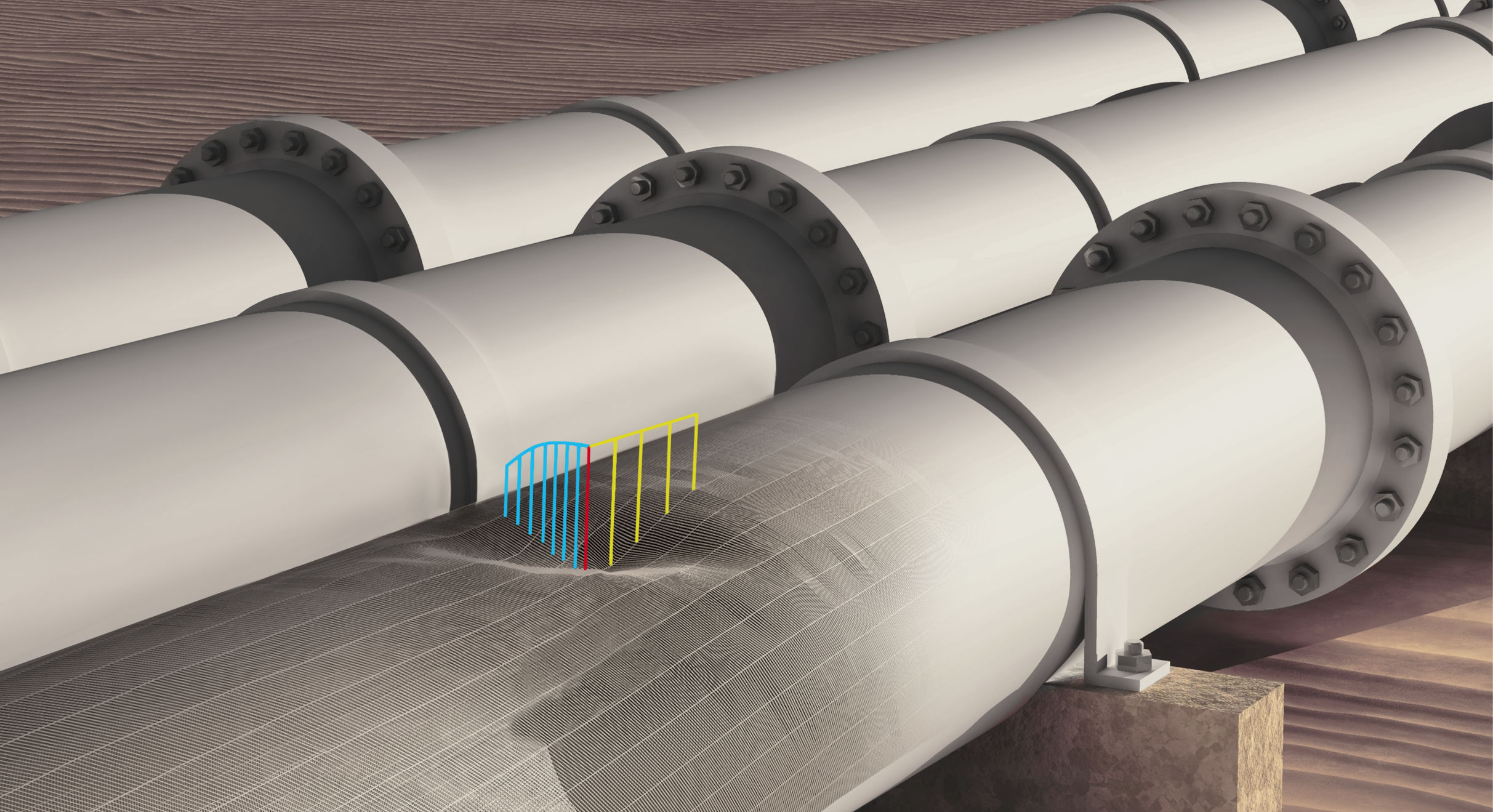

Traditional geometry inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… tools introduce a problem when it comes to traditional geometry assessment: smoothing. Smoothing and approximation techniques have the ability to alter the geometry data they’re attempting to inspect.